Moray Medical is working to improve the quality of life for the millions suffering with leaky heart valves. Using our proprietary microfluidic robotics, more cardiologists can safely and cost-effectively treat the large number of patients who need mitral valve clip therapies.

Extending the Benefits of Heart Repair

Heart mitral valve repair has not reached the masses. Open-heart surgery, the historical standard of care, is highly invasive and too risky for the vast majority who would benefit. Transcatheter mitral valve procedures, with access through the veins, are minimally invasive, but are difficult to perform. However, low trauma therapy works! The Transcatheter Edge-to-Edge Repair (TEER), or clip therapy, is rapidly becoming the new standard of care.

The 2018 COAPT trial shows that percutaneous interventions (with access through blood vessels) can be equally successful and is much less traumatic than open-heart surgery. Unfortunately, the complexity of the current mechanical instrumentation requires a long learning curve that prohibits mass adoption. A consequence only 2% of sufferers are treated and there are millions of new patients each year.

Empowering Cardiologists

Moray Medical is simplifying the percutaneous delivery of valve therapies for interventional cardiologists of all skill levels. Millions of patients will benefit from this cost-effective and easy-to-learn-and-use delivery system. A larger and more dispersed group of interventionalists will be able to successfully treat patients with leaking heart valves.

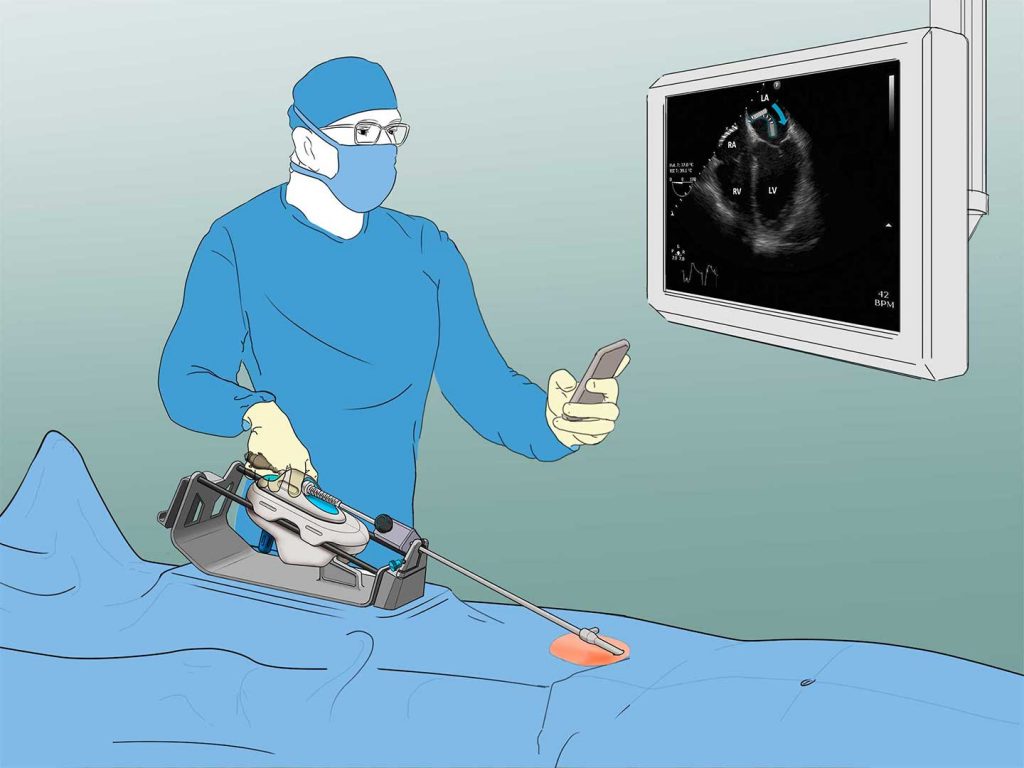

Today, when placing a valve clip, the delivery system is not intuitive. The mitral valve edge-to-edge procedure typically requires four hands and two highly skilled interventional doctors. Even the most elite teams are challenged. Implanting clips is time-consuming, expensive, and is generally performed in a few specialized urban centers.

Moray’s robotic system, with its digital user interface, enables a single hand to control the placement of a clip. Powered by microfluidics, the catheter system is fast, precise, and intuitive; yet comparable in size to existing manual systems, and costs less to manufacture.